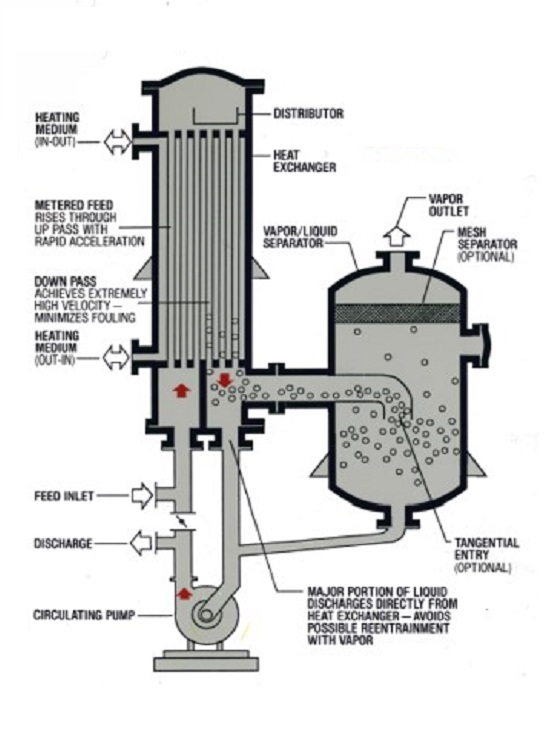

Buflovak Rising Falling Film Evaporator

Manufactured by Hebeler Process Solutions, USA

The Rising Falling Evaporator or Concentrator delivers high tube velocities which assures uniform product distribution and high coefficients of heat transfer.

The rising falling film evaporator (RFC), or recirculating version, RRFC, works on uniform metered flow entering the bottom of the steamchest and rises through the first pass with rapidly increasing velocity.

After leaving the first pass, the flow of the vapor-liquid mixture is reversed and directed downward through the second pass at an extremely high velocity. The mixture then enters the separator where the vapor and liquid are separated.

When not designed as a circulation unit, the rising falling film evaporator provides once through evaporation of heat sensitive materials, requiring minimum retention time. It is particularly adaptable to multiple effect systems but provides a lesser turn-down capability than the RRFC configuration.

Rising Falling Film Evaporator Characteristics

- High tube velocity minimizes fouling

- Able to achieve high concentrations at low temperatures

- Risk of entrainment is greatly reduced since the major portion of the liquid passes directly out of steamchest rather than being re-entrained with vapor from the separator

- System may be turned down without loss of efficiency or effectiveness

- Holding time is a matter of seconds (RFC)

- Suitable for evaporation of a wide range of liquid concentrations

- Low headroom requirement

Rising Falling Film Evaporator Product Applications

- Heat sensitive liquids requiring minimum process time

- Pure or non-crystal forming liquids

- Liquids having low to medium viscosities

- Foamy liquids

- Liquids containing fine suspended solids

- Readily handles thixotropic materials

Rising Falling Film Evaporator Application Examples

- Ammonium- Nitrate

- Apple Juice

- Cane Sugar Syrup

- Caprolactam

- Corn Syrup

- Caustic

- Coffee Extracts

- Gelatin

- Glue

- Lemon, Orange Juice

- Grape Juice

- Pineapple Juice

- Pharmaceuticals, Heat-sensitive

- Tea Extracts

- Urea and similar products