Gate Valves

Gate Valves are used for isolation of a process line in the chemical and petrochemical industries.

Wedge and Slab Gate Valves (GW & GS Series)

Manufactured by Strahman Valves Inc (US)

These valves are designed for specific applications where large diameters, jacketing, or special materials are required. The main features of our tight shut-off Gate Valves are the full bore design, the availability of metal or resilient sealing arrangements, and the choice between wedges or parallel seated designs.

Design Features:

- Jacketed wedge gate valves are mainly used in the polymer industry

- Bellows-sealed wedge gate valves with welded lip seals are suited for toxic and lethal product

- Slab gate valves are recommended for isolation of ethylene furnaces where heavy feed stocks are cracked.

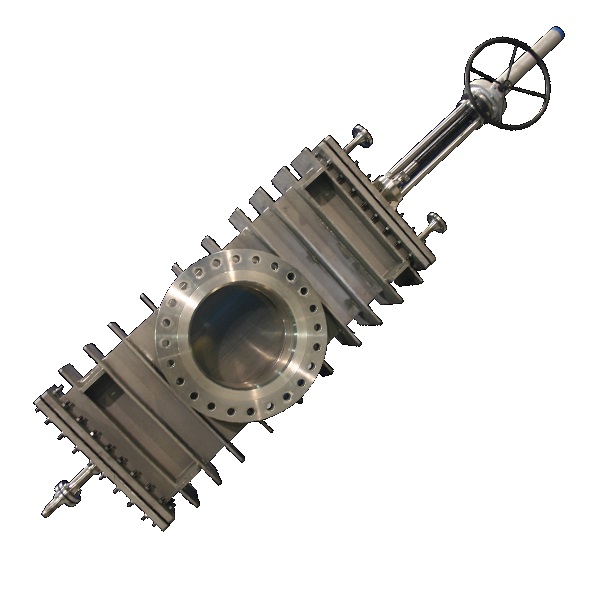

Single Disc "Slab" Gate Valves

Manufactured by Strahman Valves Inc (US)

These are slab gate valves specifically designed for delayed coking, ethylene and FCC cracking service.

The Single or “Slab” gate design provides the end user with a long term reliable solution for line isolation. The flexibility of the slab gate design including flange connections, materials of construction, and the choice of actuation - whether it is best suited for hydraulic, electric, pneumatic, or hand wheel gear operation will fit the needs of design engineers. The combination of the constant cleaning of the gate surface with every stroke along with the constant steam purge system plays a significant role in the low maintenance design and longevity of the valve.

Design Features:

- The gate and seats are in constant contact to keep the particles out of the valve body

- Steam purged for 100% positive shut off

- Capable of remote operation for complete personnel safety

- Low maintenance design for uninterrupted operations between turnarounds

- Can be electric, hydraulic, or even pneumatically operated with Manual override

- Standard sizes up to 48"

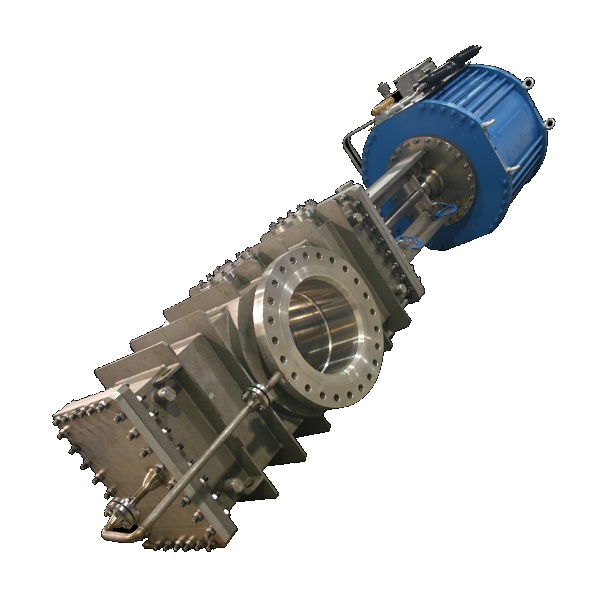

Double Disc "Slab" Gate Valves

Manufactured by Strahman Valves Inc (US)

These are slab gate valves specifically designed for delayed coking, ethylene and FCC cracking service.

The double disc gate valve has two separate stellited discs and two removable stellited seat rings; these discs are moving between two guide plates. When the two discs are in closed position, a flexible wedges system, which is located and fixed on the side of the cavity body, applies the necessary seating forces on the two discs to obtain the necessary tightness against the seats.

This design feature offers the solution to other designs that are known to become jammed due to high temperatures and the “sticking” of the discs. These discs are then “dragged” along the seats without the proper release damaging the seats and making it very problematic to seat again without using excessive amounts of steam.

A superior purging system has also been implemented with additional steam paths around the wedges system to eliminate possible coke build-up. Additional purging ports can be designed as recommended during the design phase for maximum purging efficiency.

When the valve is in open position, the flexible bellows located on the pipe is reinforced by 3 outside graphite rings which push the 2 parts of the pipe against the body seats creating a tight seal. This design improvement solves the common problem with other designs having the body cavity filled with coke blocking and the discs in half position.

Design Features:

- Two independent sealing discs for true “Block and Bleed” functionality

- Steam purged for 100% positive shut-off and inability for particles to enter the valve body or atmosphere

- Capable of remote operation for complete personnel safety

- Low maintenance design for uninterrupted operations between turnarounds

- Mechanical spreading mechanism that requires no additional force for long-term sealing capability

- Capable of manual operation for immediate operation

- Standard sizes up to 48"